Aug. 12, 2022

Aug. 12, 2022

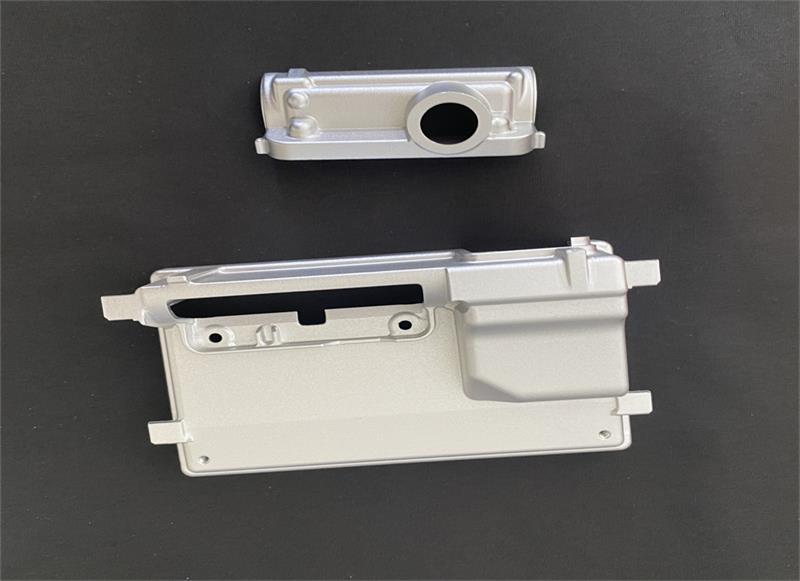

We often see rounded corner design in many products, this design is called corner obtuse, in Xu Feng quality department, you can see that many parts are used in this process.

The obtuse angle includes chamfer and round, However, they play a very important role in the process of manufacturing, assembling and using, which can not be neglected, in that case, many engineers in product design will add a chamfer or fillet once see the corner, however, adding chamfer and fillet at will, may greatly increase the cost of manufacturing products. Here we give a brief introduction to it.

1, Where to do Chamfer or rounded corner?

Design chamfer or rounded corner is mainly for safety, technology, and the appearance of decorative needs.

Parts through milling processing, it's often very sharp on the corner, we commonly used chamfering or rounded ways to remove sharp corners and burrs, in order to avoid scratches. In this case, chamfer and fillet can also remove the tip stress of these places, reduce pump and fatigue and other causes of product damage and failure.

And some parts because of the process needs, must design appropriate chamfer and fillet. The design chamfering of shaft hole fitting parts is easy to assemble, and the chamfering of gear tooth tip can not only prevent the heat treatment deformation from causing the tooth tip to reverse warping, but also prevent the tooth tip from Harden and collapse, so as to avoid affecting the meshing quality.

The design of powder metallurgy angle can make it easy to release the mould and reduce the wear, and the design of chamfer or fillet at the corner of the product structure can make the liquid flow smoothly in the mould, and make the pressure even and convenient to release the mould.

Chamfer and rounded corners are also decorative. The product appears more friendly and attractive with a chamfer or rounded corner. There are 4 kinds of chamfering methods commonly used in product design: equal chamfering, relative chamfering, reverse chamfering and plane excessive chamfering.

The equal chamfering is characterized by horizontal lines parallel to each other and cross-sectional veranda edges perpendicular to each other. When the chamfering radius is small, it will form a hard and delicate“Line”, which can reflect the exquisite and overall sense of product technology.

Related chamfer because of the virtual space outside the parts, make the whole product's volume sense significantly smaller, the product from the visual“Cut” thin, not only weakened the rectangular rigid, indifferent image, also makes the overall shape simple, enhance the overall sense of the product, is widely used in electronic products.

The shape of the deviation chamfer has the variation of the broken line, the curve, the angle and the virtual space. Compared with equal chamfering, the deviation chamfering, the surface turning and the rhythm change of the three-dimensional space produce the dynamic suggestion, which has a strong independent effect on the shape segmentation. The most typical use of mobile phone keys and computer keyboards, some electronic products open and close the cover design also uses this kind of chamfer.

The plane excessive chamfer is the most common type of chamfer, and there is no obvious parting line. Smooth transition of the body, and rich and diverse modelling, enhance the overall aesthetic of the product.

2, chamfer and rounded corner, how to choose?

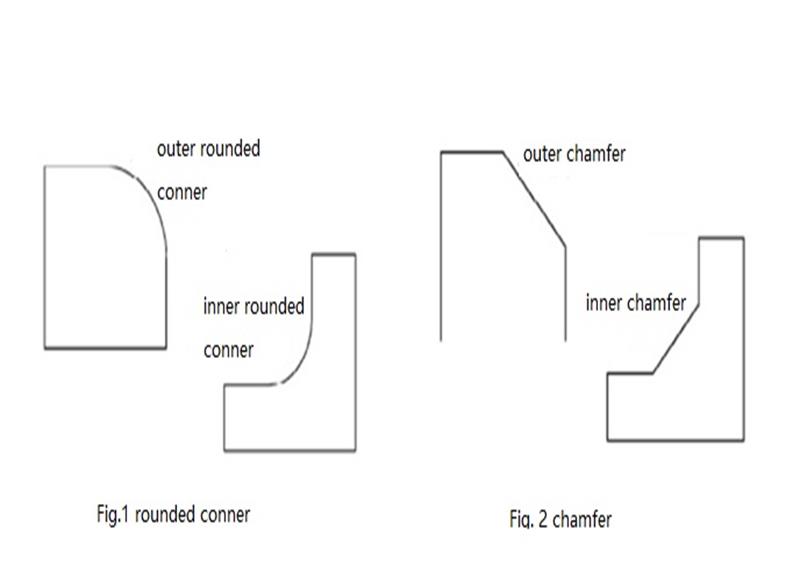

The transition of a rounded corner is smooth, with no sharp points or edges, while a chamfer forms a bevel, and no matter how the angle of the bevel changes, both sides of the bevel form sharp angles with the outline of the part, only these sharp angles are obtuse, not sharp. Therefore, the fillet is more suitable for reducing stress concentration than chamfering, and the protective performance of the fillet is better than chamfering.

In assembly relation, chamfering design often plays a leading role and is convenient for assembly, but interference should be avoided, the following picture shows the example of the round and chamfer. To ensure that there is no interference, when the outer chamfer is fixed with the inner chamfer, the outside chamfer should be greater than the inside. Similarly, when the outer fillet is matched with the inner fillet, the outer fillet must be larger than the inner fillet.

In machining, both chamfer and round can be processed by cutting and grinding, but the processing range of chamfer is wider than round, and it is easier to process. For example, a shaft is machined, the chamfering can be done with a normal lathe, while the round must be machined with a special forming tool, and the efficiency of chamfering is higher than with a round with a CNC lathe.

| comparison of chamfer and rounded conner | ||

| items | Chamfer | Rounded corner |

| purpose | holes and external characteristics | prevent the hurt and inner characteristics |

| cost | a little cheaper when manual cutting | higher than chamfer when milling |

| time | shorter | except using the round head of milling cutter, much longer |

| tool | different sizes chamfer can use the same tool | different sizes of rounded need the different tools |

So in terms of economy, chamfering is better than round, with no special requirements, the outer surface and plane preferred chamfering. The corner of the side wall of the inner cavity should be rounded as much as possible, because the corner of the tool will keep the radius arc of the tool in the process of cutting with the side edge. If the side walls of the cavity are machined to chamfer or right angles, the use of auxiliary processing equipment, such as electrical discharge machining, may result in relatively high costs.

3, How to design chamfer or round corner, then more cost-effective?

The tool cost of chamfering or round will increase proportionally with the increase of the edge radius, and the chamfering or round in any situation will cause unnecessary machining costs, before adding chamfer or rounded corners to your design, consider these four questions:

What is the role of chamfer or rounded corner?

Is the chamfer or rounded corner necessary for the part?

Is it cost-effective to add this design to the planned production?

How to check tolerances?

If it's just sampling, the cost per part is already high, and it's not cost-effective to add chamfer or fillet designs. However, if mass production takes place, the cost per part will not increase much and will be cost-effective. For those requiring a casting or forging process, fillets are not only cost-effective but also essential.

The smaller the tolerance, the higher the processing cost. If it is determined that size is not important, the chamfer can be removed from the solid model and a note added to the drawing stating that“Sharp edges are obtuse and given range values for obtuse chamfer or arc.

Therefore, in order to save cost, a necessary principle of chamfer and fillet design is to meet the needs of the premise, as little as possible to add strict tolerance, large-scale fillet and chamfer. If you have more questions about chamfer or round, feel free to contact us and ask for more details.